Heavy Duty Pallet Storage Drive in Rack for Industrial Warehouse

Heavy Duty Pallet Storage Drive in Rack for Industrial Warehouse Welfor drive in rack is suitable for storing goods of f

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | DIR-001 |

| Weight | More Than 1,000kg |

| Closed | Open |

| Development | Conventional |

| Serviceability | Common Use |

| Color | Blue and Orange |

| Certificate | Ce, SGS |

| Surface Treatment | Powder Coated |

| Transport Package | Banding, Plastic Film, Wood Pallet, Carton |

| Specification | according to pallet size and weight |

| Trademark | Welfor |

| Origin | Nanjing |

| HS Code | 73089000 |

| Production Capacity | 5, 000 Ton/Month |

Product Description

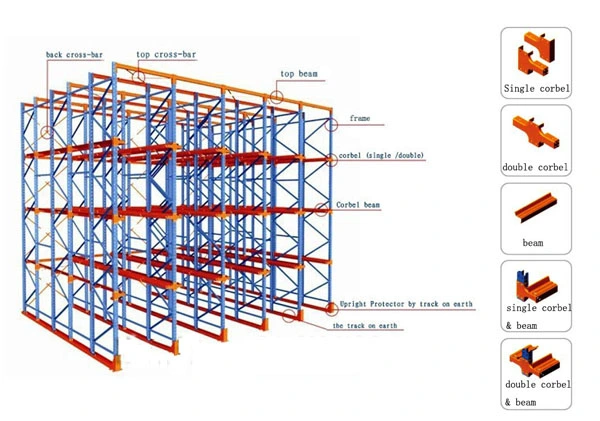

Heavy Duty Pallet Storage Drive in Rack for Industrial WarehouseWelfor drive in rack is suitable for storing goods of few varieties by great quantity. Fork lifer may go into the passage of each row of the rack improving the utility ratio of warehouse.

Using minimal space for access aisles and lanes, Drive-in Racking provides a high-density and very space-efficient bulk storage system. With the first pallet into a lane being the last out, stock selectivity is restricted, but when loads are delivered and dispatched in batches, this is not a difficulty. Pallets are stored on joist in the depth of the racking and trucks enter to deposit or retrieve loads.

Features

- Made of continuous rows of upright frames interconnected by spacers

- Forklift trucks drive along each aisle (lane) to store or retrieve pallets

- Each aisle consists of several levels of pallet support rail

- Pallets are placed on the pallet support rail one after another along the aisles

- Top and back bracings are used to stabilize system structure

- All components are epoxy powder coated except the galvanized footplates

- Accessories include shim, upright protector, forklift guide rail

Technicial data for drive in rack

| Products | Heavy Duty Pallet Rack | Medium/Light Duty Rack |

| Loading Capacity | 1000-5000KG/layer | 100-1000KG/layer |

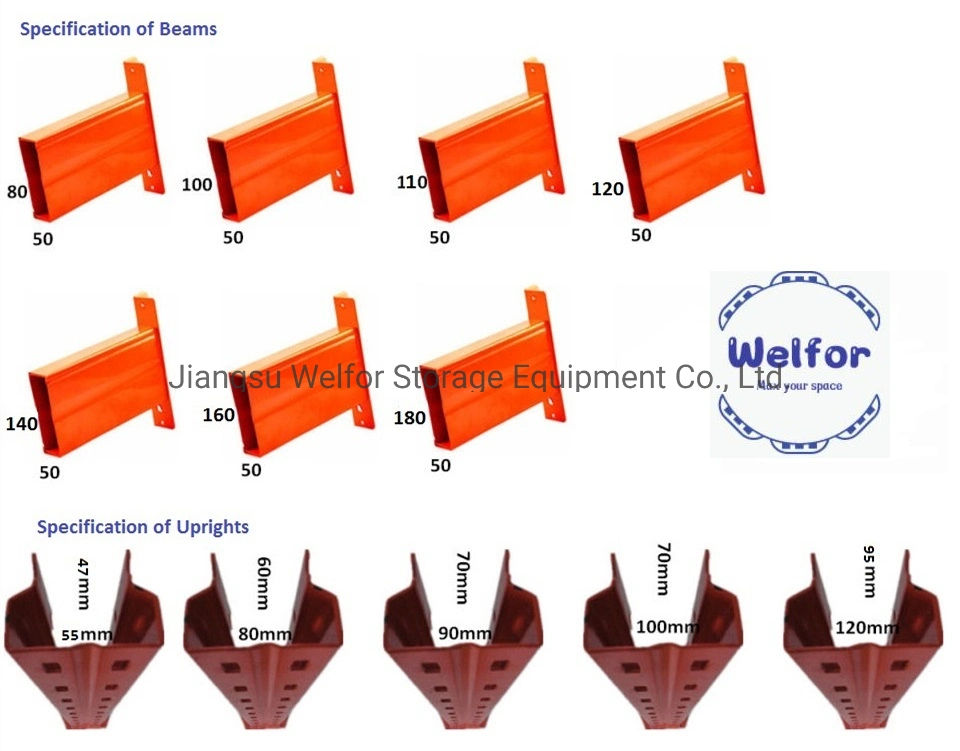

| Specification | Main Racking: L2000*D1200*H4800mm*4layers (Designed by different demands) Beam:L1800~5000mm Layer board: 1.5~2.5mm Customized sizes and colors are welcomed | Main Racking: L1500*D1200*H3000mm*4layers (Designed by different demands) Beam: L1200~2500mm Layer board: 1.0~2.0mm Layers: steel panel/net or wood veneer Customized sizes and colors are welcomed |

Production process

Packing and loading photos

Please provide information for quick quotation

1. Pallet Size (Length*Width*Loading Height in mm)2. Layout or Dimension (Length*Width*Net Height in mm) of your warehouse3. Rack Size (Length*Width*Depth in mm) if you are available or we shall design for you4. How many bays and levels if available5. Loading Capacity(kg) of each level or each pallet

FAQ

1, What is MOQ limitation for rack system?++ NO. But large purchase will bring competitive prices, 20FT container ( 10T~13T) is highly recommended, so that production can be better handled.

2, What is the lead time++ As per 20FT container loading, manufacture time is about 10-15 days; Regarding some customized items 20-25 days will be covered.

3, What is payments methods you can accept?++ T/T and L/C are welcomed.

4, How about your sample delivery?++ Short section of uprights and beams can be provided free of charge. But the freight will be collected upon your duty.

5, What is warranty for your rack system?++ All rack items will be warrantied against manufacture's defects.++ To avoid any shortage or missing components, we will provide 1%~2% spare parts besides basic ones.

More Products

Contact information

Related Products

-

![Cold Storage Room/Freezer Room Used in Farm and Warehouse]()

Cold Storage Room/Freezer Room Used in Farm and Warehouse

-

![Vertical Lift Smart Warehouse Rack System Automatic Warehouse Intelligent Storage]()

Vertical Lift Smart Warehouse Rack System Automatic Warehouse Intelligent Storage

-

![Direct Factory Sale Advanced Steel Galvanized Material Storage Cost of Warehouse Construction]()

Direct Factory Sale Advanced Steel Galvanized Material Storage Cost of Warehouse Construction

-

![Giantmay 3 Sided Retail Metal Revolving Display Wire Rotating Shelf]()

Giantmay 3 Sided Retail Metal Revolving Display Wire Rotating Shelf